Container Identification and Color Options

June 21, 2021

How to easily identify your bulk containers

Clients are often looking to differentiate their containers based on color—a simple enough request. However, there are several things to consider before looking into this option.

First and foremost, getting a nonstock color on the schedule will take a minimum product order of two truckloads. The main reason for this is that we must pause production to make the color change, and we prefer to run a lot of product all at once to reduce wasted material. The wasted material is generated when we must purge the mold of the previous color being ran to prevent a mix, which would typically be black. It never hurts to ask if we can run fewer totes since we will sometimes have another color order, and we made extras. Or, if you are lucky, they haven’t been run yet, and we can add your order to the back of it.

What are the standard custom colors?

The standard colors we offer are black, gray, blue, and green. Orders in these colors will have minimal cost increases and lead times. You will find most products will be stocked in black since it is the most popular, but we also stock some items in blue, gray, and green (though only a few). Container lids are almost always black since we prefer to make them from 100% recycled material.

What are the nonstandard custom colors?

The nonstandard color options are yellow, purple, orange, and red. The primary difference is going to be the cost and lead times on your order.

So why doesn’t RPP stock an assortment of colors on the most popular products?

Well, the increased production costs and lead times are the primary reason. The secondary reason is a lack of demand. Things may change in the future if folks are bringing us their requests and we see a trend. So, again it never hurts to ask.

What other options are there for clients if a custom color is not going to be viable?

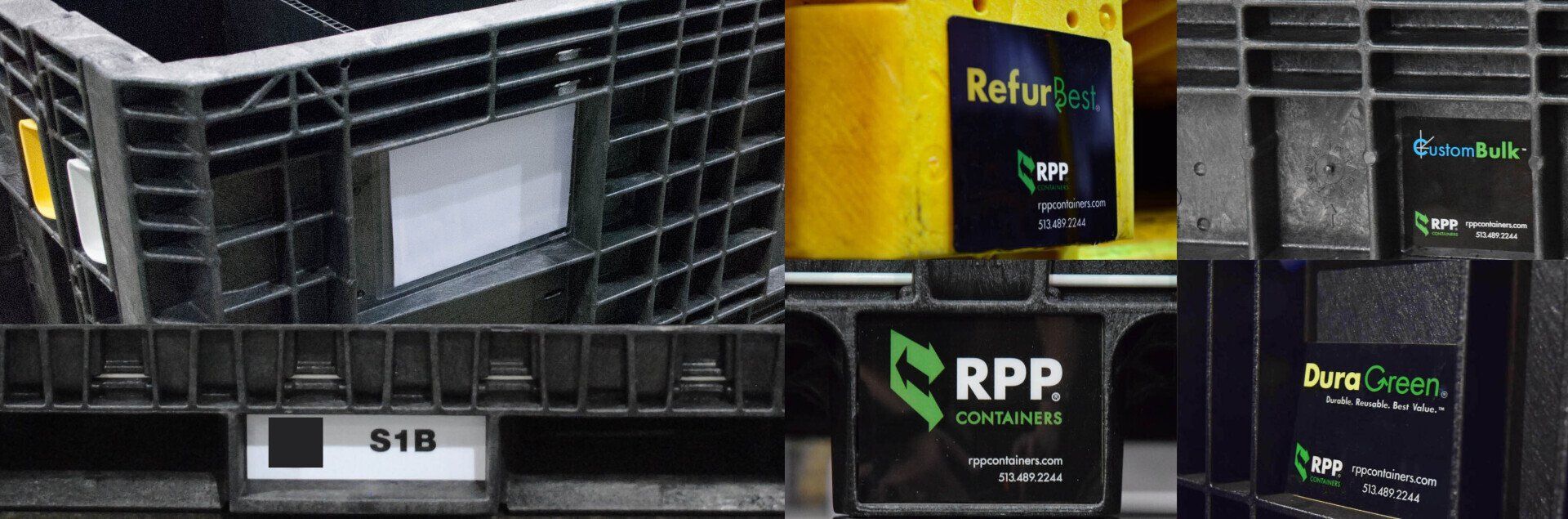

We would recommend looking into ID tags for your totes. They are much less expensive than a color change, and they are more customizable since they are printed instead of molded. Not to mention they can be removed or updated. If you have us mold you a run of funky purple containers, you might likely be stuck with that decision. Our products have sections in their mold to support ID tags, label plates, and cardholders. Let our team guide you through the many options to see what works best for your vision.

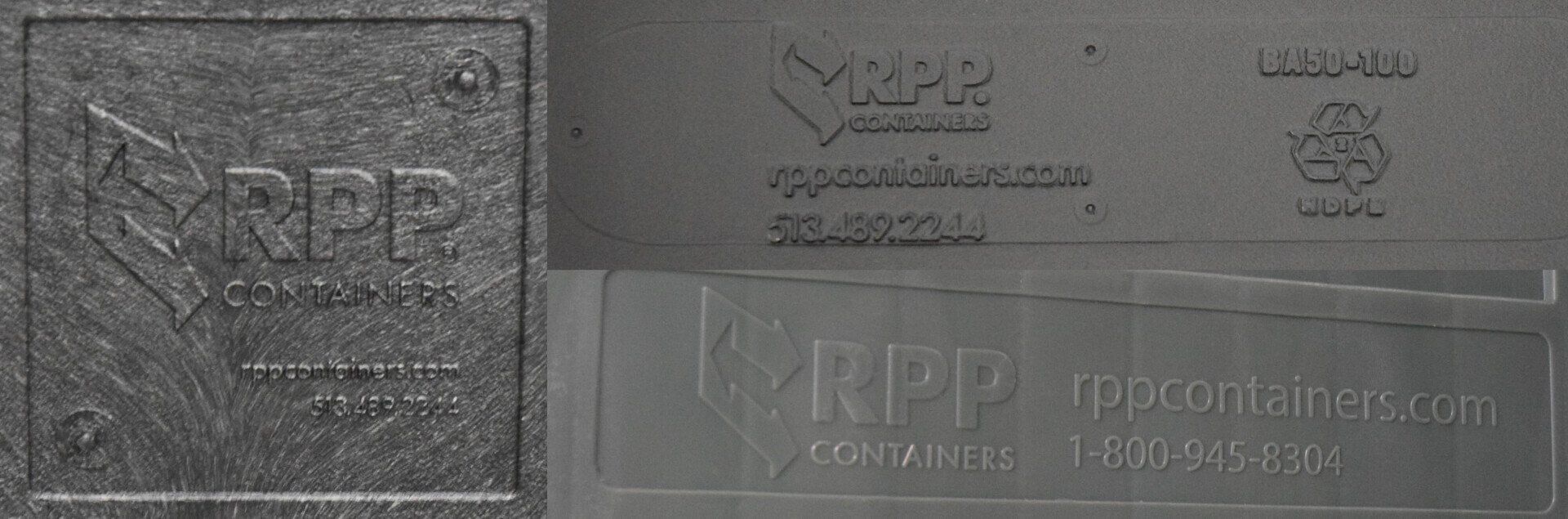

A more expensive option, but one we offer, is having a plate made to mold your company name/logo into the container. Though more subtle than a true ID tag, this is common practice with automotive folks. Fair warning: this will increase lead times as the plate needs to be made first before running your order.

Please do not hesitate to reach out if you have any questions about this topic or any of our products.

Please do not hesitate to reach out if you have any questions about this topic or any of our products.

When it comes to preserving the freshness and quality of your coffee beans, every detail matters—especially the storage containers you choose. In the world of coffee production, maintaining the integrity of the beans from roasting to final delivery is essential. That's where RPP Containers steps in with their reliable plastic hopper bottom containers, a game-changer for anyone involved in the coffee business, from roasters to retailers.

In the world of material handling and logistics, one size does not fit all. That's where RPP Containers steps in with its innovative CustomBulk solutions, designed to address the unique challenges businesses across various industries face. Whether you're dealing with oversized components or sensitive materials or need something beyond the standard container offerings, CustomBulk by RPP Containers is your go-to for tailored, practical solutions.

In the ever-evolving world of industrial storage, reliable, efficient, customizable bulk containers are paramount. Companies across various sectors—from manufacturing to logistics—require storage solutions that meet their unique specifications and enhance operational efficiency. This is where RPP Containers steps in with its innovative custom bulk containers designed to address these precise needs.

In the world of industrial storage and transportation, efficiency and durability are paramount. As businesses strive to optimize their operations, the demand for innovative storage solutions has never been higher. One such innovation that has gained significant traction is custom plastic bulk containers with ramp walls. These containers are revolutionizing the way industries handle bulk materials, offering many benefits catering to various needs. In this blog post, we will explore the advantages of these containers, their applications, and why they are becoming the go-to choice for many businesses.

Bulk containers are an essential part of many industrial and commercial operations, providing a convenient and scalable solution for transporting and storing a wide variety of goods. However, as businesses evolve and adapt to changing needs, there often arises a necessity to modify the walls of these bulk containers to better suit their specific requirements. Whether it’s reinforcing the structure, adding access points, or enhancing insulation, wall modifications can significantly enhance the efficiency and functionality of bulk containers.

When shipping and storing goods in bulk containers, ensuring the safety and integrity of the products is of the utmost importance. This is where bulk container dunnage comes into play. Dunnage refers to materials used to support and secure cargo during transportation, and when it comes to bulk containers, the use of dunnage becomes even more crucial.

Returnable bulk containers, a sustainable choice, are extensively used in the automotive supply chain to transport and store various components and materials required in manufacturing. Their durable and reusable design makes them an economical option and a significant step towards reducing single-use packaging and promoting environmental responsibility.

Agriculture, particularly fruit and vegetable growing and processing, is a very demanding business. It requires highly efficient, strong packaging and is resistant to harsh environments. RPP Containers has been at the forefront of meeting these needs. Our DuraGreen vented harvest bins and solid wall bulk bins protect produce, ensure quality, and preserve freshness from fields to supermarkets.

One game-changing innovation that has emerged in the industry is the 40 x 48 x 43 Stackable Foldable IBCs. These versatile containers offer a wide range of benefits that revolutionize the way goods are transported, stored, and handled. This article delves into the features and advantages of 40 x 48 x 43 Stackable Foldable IBCs, emphasizing their role in enhancing efficiency and promoting sustainability.