1-800-945-8304 | contact@rppcontainers.com | Live Chat

Maximizing Product Protection: The Importance of Bulk Container Dunnage

The Importance of Bulk Container Dunnage

When shipping and storing goods in bulk containers, ensuring the safety and integrity of the products is of the utmost importance. This is where bulk container dunnage comes into play. Dunnage refers to materials used to support and secure cargo during transportation, and when it comes to bulk containers, the use of dunnage becomes even more crucial.

What is Bulk Container Dunnage?

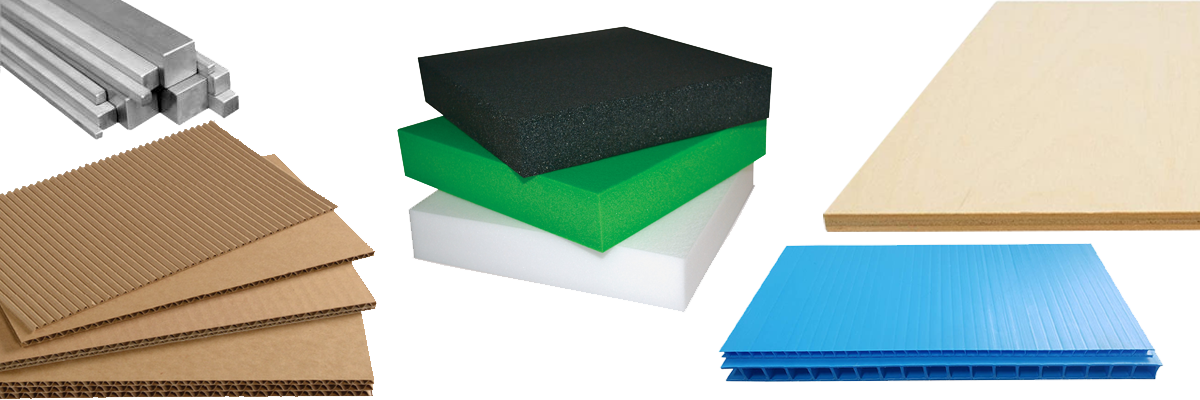

Bulk container dunnage typically consists of materials such as foam, corrugated inserts, solid plastic, fabric, steel and wood dunnage. Its primary function is to prevent damage caused by the movement of goods within the container during transit. This is particularly important for fragile or sensitive products such as electronic components, glassware, or automotive parts that need to arrive at their destination in perfect condition.

Importance of Proper Dunnage

Properly securing and cushioning the products inside bulk containers with dunnage provides security, preventing damage and maximizing the efficiency of the shipping process. Without adequate dunnage, goods are at risk of shifting, colliding or being compressed during transportation, leading to potential losses for the supplier and dissatisfaction for the customer.

Types of Bulk Container Dunnage

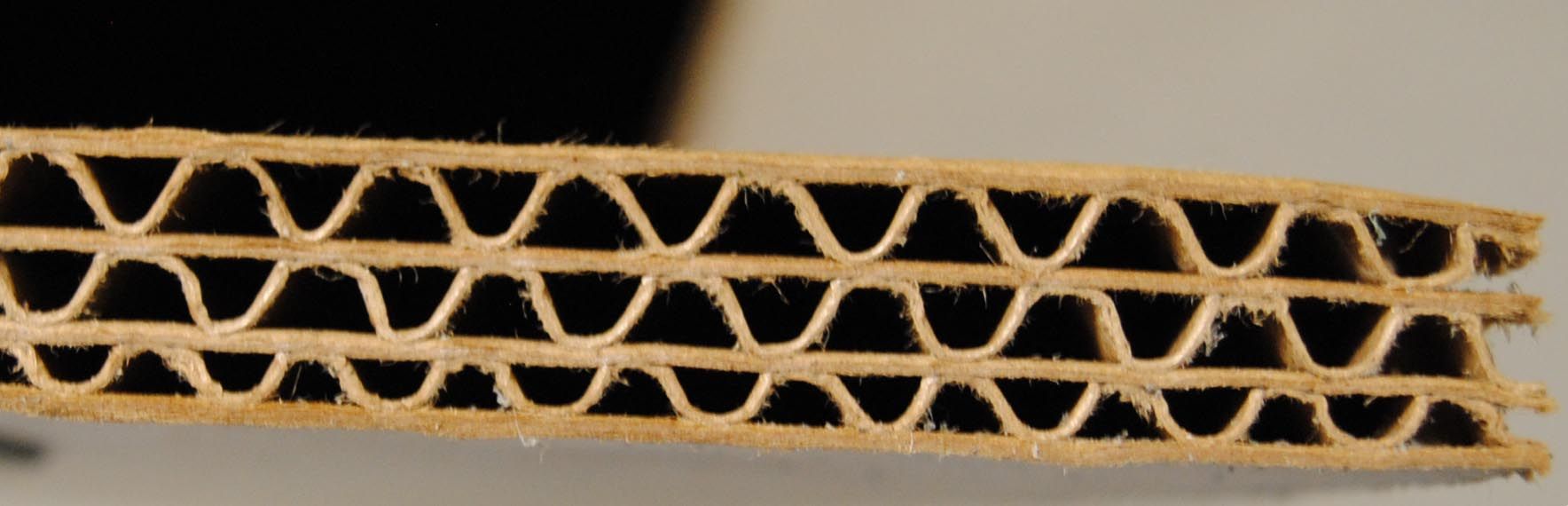

Corrugated Cardboard Dunnage

Corrugated cardboard is a paper-based material that is 100% recyclable. It is flexible, strong, and available in single, double, and triple-wall thicknesses. Corrugated cardboard is a lightweight and cost-effective option. Corrugated cardboard is traditionally used for partitions and divider dunnage. Corrugated dunnage keeps the product separated and in place so that during transit, the product will not move or make contact with other products and cause damage.

Corrugated Plastic Dunnage

Corrugated plastic is durable and reusable, unlike cardboard. It is designed for repeated use and is resistant to puncture, tearing, and impact damage. Corrugated plastic is also moisture resistant and will not mold mildew, or rust. It is easy to score, crease, fold, nail, staple, and drill. Corrugated plastic dunnage inserts can be designed to accommodate applications and industries where wood and cardboard can not be used.

Foam Dunnage

Foam can be used as a divider and buffer between products. Foam dunnage is lightweight and provides shock and vibration protection. Foam can be easily cut to fit any shape of a container or product. The application determines the type of foam used. As a lightweight material, foam cuts down on a container's overall weight compared to other options.

Solid Plastic Dunnage

Solid plastic dunnage is made from high-density polyethylene. It is ideal for heavier parts, has extreme durability, and is ideal for objects with sharp edges or parts. Solid plastic dunnage is used as a buffer between parts, absorbs shock, and is a popular option in the automotive industry. It is also weather resistant, will not mold or rot like cardboard or wood, and is 100% recyclable.

Fabric Dunnage

Fabric dunnage is versatile and flexible and offers capabilities that other rigid dunnage cannot. Fabric dunnage is available in multiple combinations. Industrial fabric dunnage is ideal for protecting uniquely shaped parts for storage and transit. Don't let the word fabric fool you. Fabric dunnage can be durable and strong enough to withstand wear and tear from repeated contact with sharp metal and plastic. Fabric dunnage must have a framework to support it. Fabric dunnage collapses to fit in the bottoms of containers for condensed loads and reduced return freight expenses. Reusable fabric dunnage is washable and easy to clean without applying specialty coatings or films.

Steel and Wood Dunnage

Steel and wood are often used for blocking and bracing heavy and large industrial parts and components. Blocking involves the use of dunnage to prevent the movement of goods within the container. At the same time, bracing is the process of securing the goods in place to withstand the forces of transportation.

Benefits of Using Bulk Container Dunnage

- Damage Prevention: The primary benefit of bulk container dunnage is preventing damage to the products being transported. By minimizing movement and impact, dunnage ensures that items arrive safely.

- Cost Efficiency: While the initial investment in dunnage materials is necessary, the peace of mind and cost savings from preventing damaged goods far outweigh the expense. It minimizes the need for replacements and refunds due to damaged products.

- Customer Satisfaction: Reliable dunnage solutions contribute to delivering products in optimal condition, leading to increased customer satisfaction and loyalty.

- Environmental Impact: Many dunnage materials are reusable and recyclable, allowing you to contribute to sustainable shipping practices and reduce the environmental impact of packaging waste. This sense of accomplishment is a significant benefit of using bulk container dunnage.

Conclusion

In the world of bulk container shipping, proper dunnage is essential to ensuring the safe and efficient transportation of goods. Whether it's foam, corrugated inserts, solid plastic, fabric, steel, or wood dunnage, investing in the right dunnage solutions can significantly improve the integrity of shipped products and, ultimately, the success of the supply chain. By prioritizing the use of bulk container dunnage, companies can protect their products, reduce costs, and enhance their reputation as reliable suppliers committed to delivering high-quality goods.

Do you have questions?

If you think you have an application that requires custom dunnage, or if you have questions call us at 513-489-2244 or contact us and send us a message.