Sustainable Packaging Strategy - Reduce, Reuse, Recycle

June 25, 2021

At the center of a sustainable packaging strategy is “Re-Use”

With over 20 years in the returnable packaging industry, we can say with confidence at RPP that we have seen everything regarding the use and abuse of returnable plastic bulk bins. RPP is a leading source for complete life cycle support, as a stocking distributor of both new and reconditioned bins, with a large indoor wash bay and repair/recycling operations.

A client recently asked RPP to generate inspection guidelines for their operators to determine whether bins are in safe and usable condition as they cycle through the supply chain. The request was a fun opportunity to flip through photos and generate “Go / No-Go” visual guidelines.

What is the criteria for a used bulk container to become a RefurBest used bulk container?

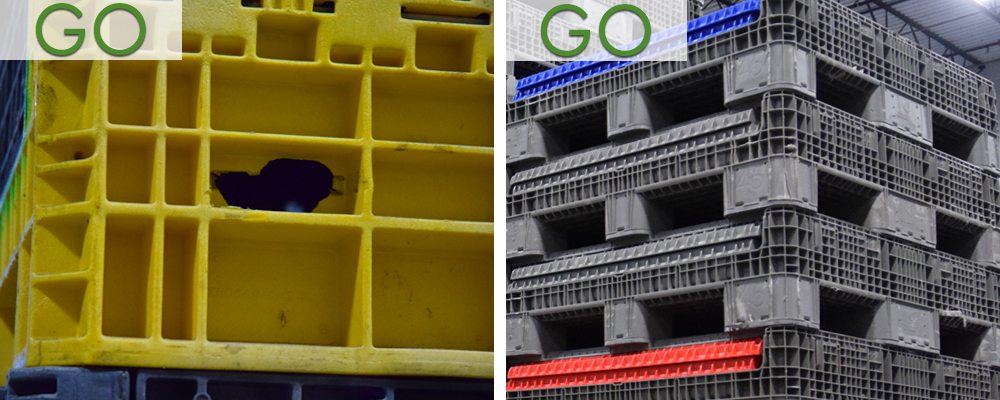

Inspection Point #1: Feet and Corners

Feet and Corners: GO

The bulk containers load is carried through the feet and rib structure, down to the ground. 80% or more of the load is carried in the four-corners. Therefore, corners and feet must be damage-free to ensure that weight is transferred vertically down through the corners and fully supported on an even floor or racking surface.

Feet and Corners: NO-GO

Missing or damaged feet are the most critical inspection point and number one reason to remove a bin from circulation. The bulk container's load is carried vertically in the corners down to the ground. Missing or damaged feet interrupts the transfer of weight and is a

"NO-GO"

condition.

Inspection Point #2: Fork straps

Fork straps: GO

Fork straps are the second critical inspection point for used bulk containers. Missing fork straps create an unsafe condition when handling bins by fork lifts or fork trucks.

Fork straps: NO-GO

If a bulk container is missing or has a damaged fork strap, it is in a

“NO-GO”

condition.

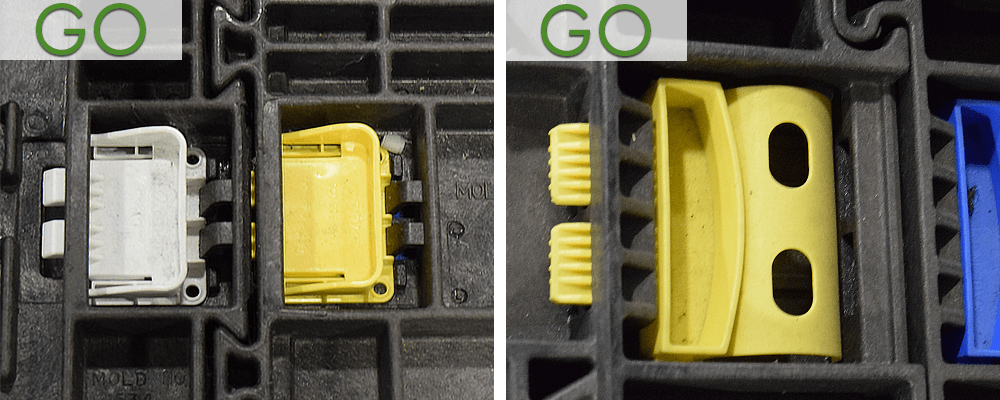

Inspection Point #3: Hinge/latches

Hinge/latches: GO

Latches are a critical part of the bulk container functionality. Latches ensure that the connecting sidewalls are securely engaged and locked into place. Also, that drop doors are positively engaged to the sidewall.

Hinge/latches: NO-GO

Inspect that hinges and latches are present, not damaged, and have a free range of motion. Inspect the condition of the locking tabs. If the latch tabs are broken, then the drop door or sidewall can not safely engage and compromise the bulk container's integrity. Missing and damaged tabs or latches are in

"No-Go"

condition.

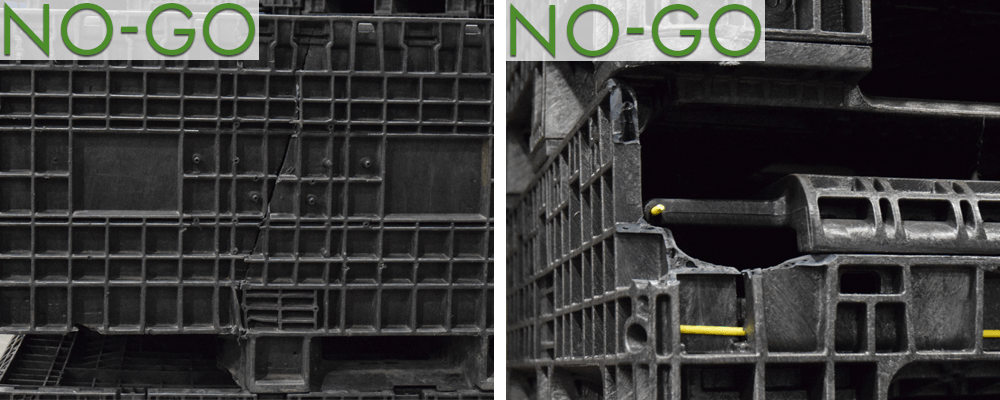

Inspection Point #4: Sidewalls

Sidewalls: GO

Cosmetic or minor rib damage to the sidewall of the bulk container is acceptable and contributes to only a minor reduction in bin performance.

Sidewalls: NO-GO

Bulk containers that have sidewalls with vertical cracking or damage along stacking rail are “NO-GO” conditions. Sidewalls with damaged fingers or hinge rods that prevent proper engagement to the base are also NO-GO conditions.

Inspection Point #5: Drop door

Drop doors: GO

Bulk containers must have fully functioning drop doors with fully functioning latches and tabs. Bulk container drop doors also require fully functioning hinges or rods that securely attach them to the container wall.

Drop doors: NO-GO

Missing or damaged drop doors prevent the vertical transfer of load to the floor. Bulk containers with missing or damaged drop doors are a

“NO-GO”

condition.

If you have questions about our

clean and repair program

,

container buy back and recycling

,

RefurBest Used Bulk Containers

, or any of our other

bands

or

services

please

contact us by sending us a message

or calling 513-489-2244 to speak with an account manager.

In the fast-paced worlds of agriculture, manufacturing, food and beverage, seed and feed, and logistics, efficiency isn't just a buzzword; it's a necessity. Handling bulk materials, such as seeds, grains, pellets, resins, and powders, can be a logistical nightmare if you're stuck with outdated or unreliable containers.

In today’s fast-paced agricultural industry, efficiency, food safety, and durability are more important than ever. One of the biggest improvements in produce handling has been the shift from traditional wooden crates to plastic harvest bins. Built with FDA-approved polypropylene and designed for maximum strength.

Our agricultural bulk containers are designed to handle a wide range of products, including fresh produce, root vegetables, grains, nuts, and other field commodities. Made from durable, FDA-approved plastic, these containers are ideal for both field use and storage in facilities. They won’t splinter, rot, or absorb moisture like wooden crates, making them a more hygienic and long-lasting solution for farmers and growers.

At RPP Containers, we understand that no two businesses are alike. Whether you're in manufacturing, distribution, or logistics, your material handling needs are unique. That's why we specialize in custom bulk containers designed to meet your specific requirements, optimize efficiency, and enhance your supply chain. In this blog, we'll explore the benefits of custom bulk containers and how RPP Containers can help you find the perfect solution.