What is Bulk Container Dunnage?

emilyw • September 22, 2021

What is Dunnage?

What is dunnage, and what does it have to do with bulk containers? The word "

dunnage

" is a term that describes packaging components that fit inside a bulk container. Examples of interior packaging components are blocks, boards, planks, and plastic or metal bracing used to secure, protect, and support parts and products for and during transport.

What are the materials used for dunnage?

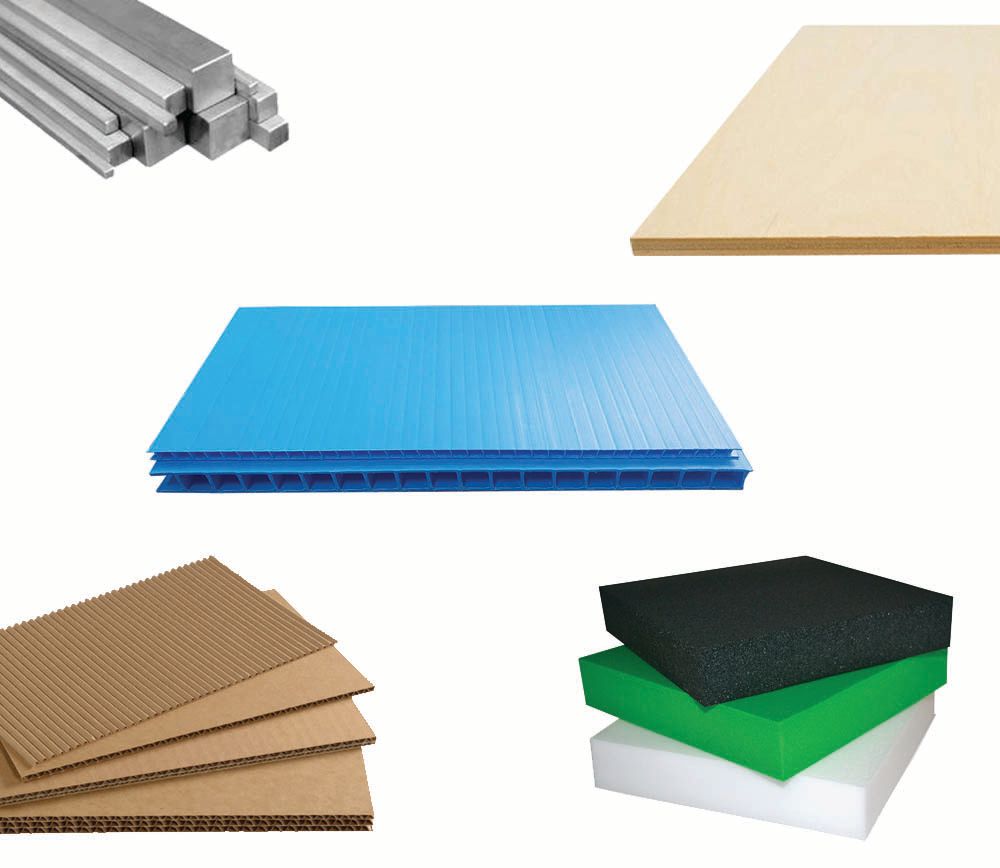

Dunnage can be made from multiple types of materials or combinations of materials. At RPP Containers, we use a wide variety of materials ranging from but not limited to corrugated materials, fabric, plastics, metals, foams, and wood.

Several materials can be used to create dunnage. The application's environment, the product's weight, storage time, and type of handling required are all factors considered when designing dunnage and what material or materials are required to give maximum protection to your products.

Materials commonly used for dunnage:

Several materials can be used to create dunnage. The application's environment, the product's weight, storage time, and type of handling required are all factors considered when designing dunnage and what material or materials are required to give maximum protection to your products.

Materials commonly used for dunnage:

- flexible foams

- foam

- solid plastics

- corrugated plastic

- corrugated cardboard/paper

- fabric

- steel

- aluminum

- wood

Foam Dunnage

Foam can be used as dividers and buffers between products. Foam dunnage is lightweight and provides shock and vibration protection. Foam can be easily cut to fit any shape of a container or product. The application determines the type of foam that is used. With foam being a lightweight material, it cuts down on a container's overall weight compared to other material options.

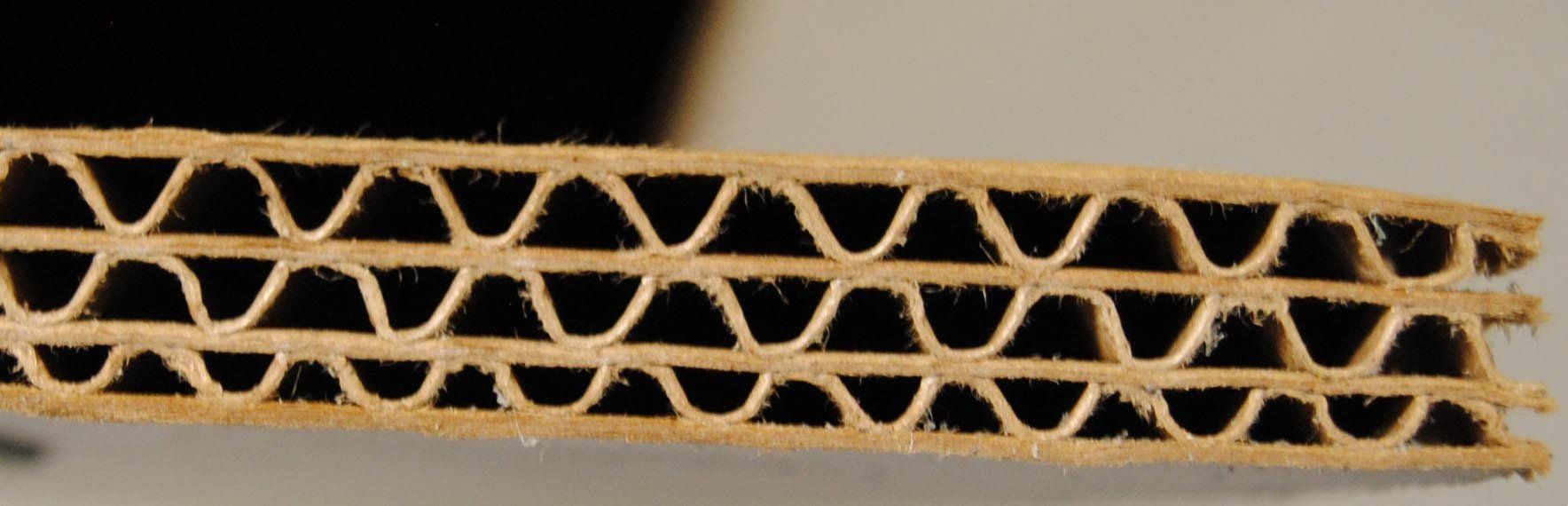

Corrugated Cardboard Dunnage

Corrugated cardboard is a paper-based material and is 100% recyclable. Corrugated cardboard is flexible and strong and is available in single, double, and triple-wall thicknesses. Corrugated cardboard is a lightweight and cost-effective option. Corrugated cardboard is traditionally used for partitions and divider dunnage. Corrugated dunnage keeps the product separated and in place so that during transit product will not move or make contact with other products and causing damage.

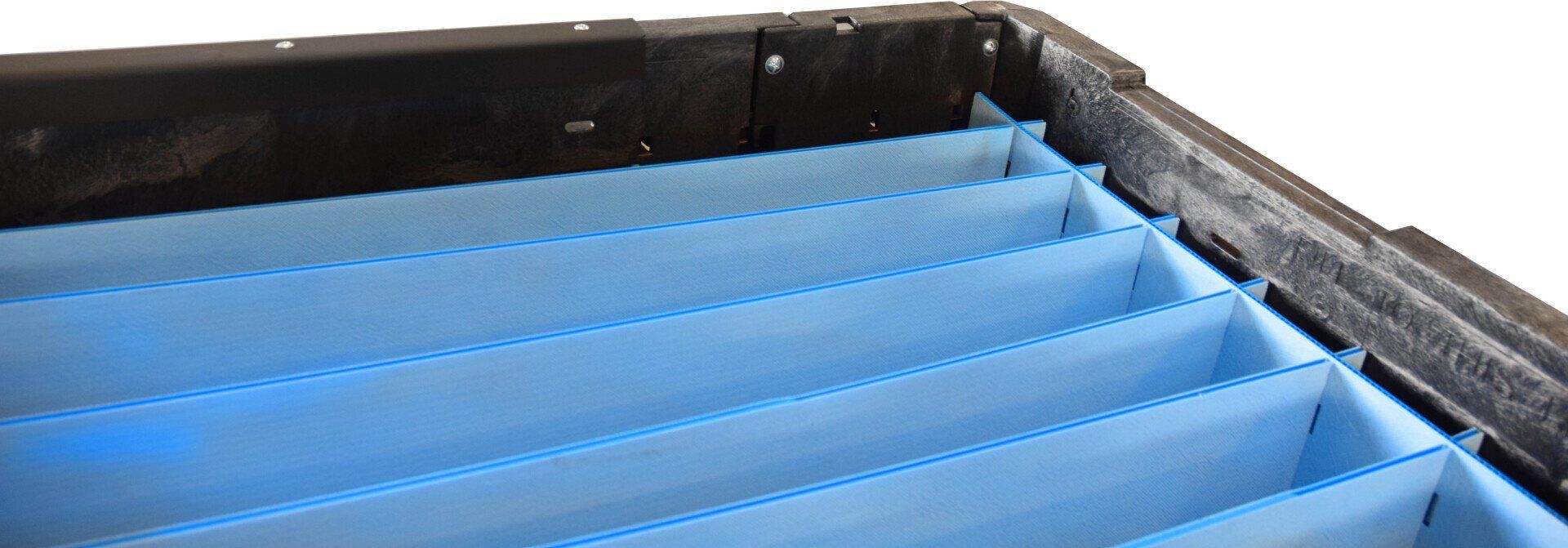

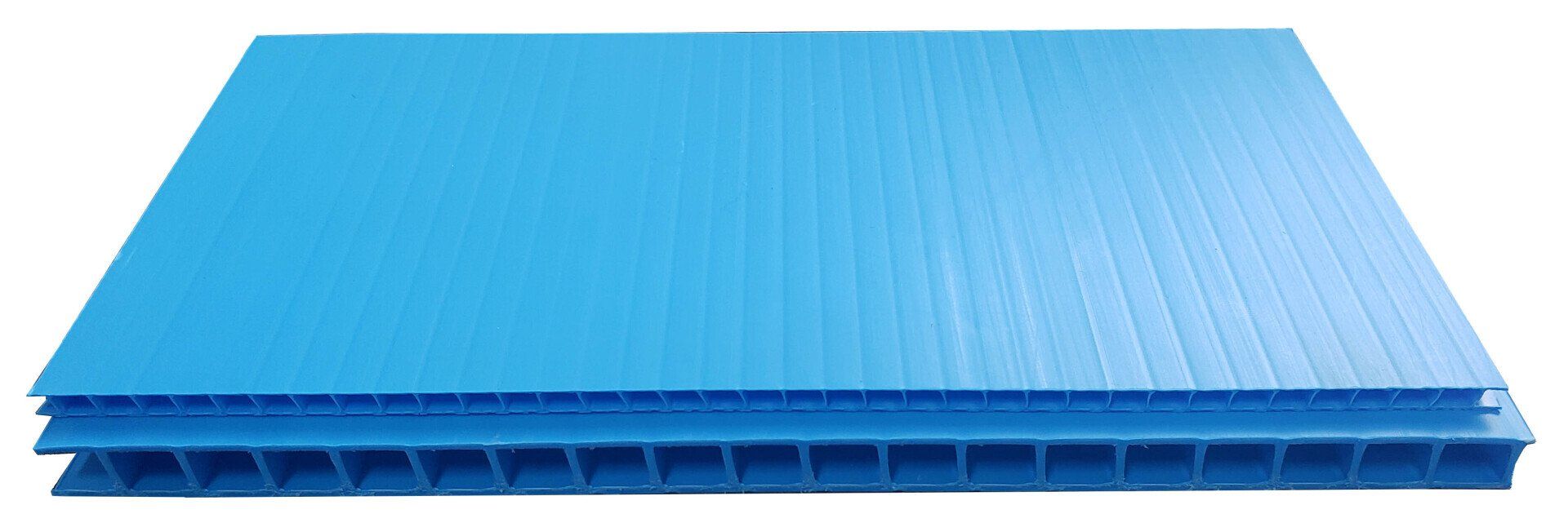

Corrugated Plastic Dunnage

Corrugated plastic is durable and reusable, unlike cardboard. Corrugated plastic is designed for repeated use and is resistant to puncture, tearing, and impact damage. Corrugated plastic is moisture resistant and will not mold, mildew, or rust. Corrugated plastic is easy to score, crease, fold, nail, staple, and drill. Corrugated plastic dunnage inserts can be designed to accommodate applications and industries where wood and cardboard can not be used.

Solid Plastic Dunnage

Solid plastic dunnage is made from high-density polyethylene, is ideal for heavier parts, has extreme durability, and is ideal for objects with sharp edges or parts. Solid plastic dunnage is used as a buffer between parts and absorbs shock and is a popular option in the automotive industry. Solid plastic dunnage is weather resistant, will not mold or rot like cardboard or wood, and is 100% recyclable.

Fabric Dunnage

Fabric dunnage is versatile and flexible and offers capabilities that other rigid dunnage cannot. Fabric dunnage is available in multiple combinations. Industrial fabric dunnage is ideal for protecting uniquely shaped parts for storage and transit. Don't let the word fabric fool you. Fabric dunnage can be durable and strong enough to withstand wear and tear from repeated contact with sharp metal and plastic. Fabric dunnage must have a framework to support it. Fabric dunnage collapses to fit in the bottoms of containers for condensed loads and reduced return freight expenses. Reusable fabric dunnage is washable and easy to clean without the need to apply any specialty coatings or films.

Steel and Wood Dunnage

Steel and wood are often used for blocking and bracing heavy and large industrial parts and components.

If you think you have an

application

that requires

custom dunnage

, or if you have questions call us at 513-489-2244 or

contact us

and send us a message.

In the world of material handling and logistics, one size does not fit all. That's where RPP Containers steps in with its innovative CustomBulk solutions, designed to address the unique challenges businesses across various industries face. Whether you're dealing with oversized components or sensitive materials or need something beyond the standard container offerings, CustomBulk by RPP Containers is your go-to for tailored, practical solutions.

In the ever-evolving world of industrial storage, reliable, efficient, customizable bulk containers are paramount. Companies across various sectors—from manufacturing to logistics—require storage solutions that meet their unique specifications and enhance operational efficiency. This is where RPP Containers steps in with its innovative custom bulk containers designed to address these precise needs.

In the world of industrial storage and transportation, efficiency and durability are paramount. As businesses strive to optimize their operations, the demand for innovative storage solutions has never been higher. One such innovation that has gained significant traction is custom plastic bulk containers with ramp walls. These containers are revolutionizing the way industries handle bulk materials, offering many benefits catering to various needs. In this blog post, we will explore the advantages of these containers, their applications, and why they are becoming the go-to choice for many businesses.

Bulk containers are an essential part of many industrial and commercial operations, providing a convenient and scalable solution for transporting and storing a wide variety of goods. However, as businesses evolve and adapt to changing needs, there often arises a necessity to modify the walls of these bulk containers to better suit their specific requirements. Whether it’s reinforcing the structure, adding access points, or enhancing insulation, wall modifications can significantly enhance the efficiency and functionality of bulk containers.

When shipping and storing goods in bulk containers, ensuring the safety and integrity of the products is of the utmost importance. This is where bulk container dunnage comes into play. Dunnage refers to materials used to support and secure cargo during transportation, and when it comes to bulk containers, the use of dunnage becomes even more crucial.

Returnable bulk containers, a sustainable choice, are extensively used in the automotive supply chain to transport and store various components and materials required in manufacturing. Their durable and reusable design makes them an economical option and a significant step towards reducing single-use packaging and promoting environmental responsibility.

Agriculture, particularly fruit and vegetable growing and processing, is a very demanding business. It requires highly efficient, strong packaging and is resistant to harsh environments. RPP Containers has been at the forefront of meeting these needs. Our DuraGreen vented harvest bins and solid wall bulk bins protect produce, ensure quality, and preserve freshness from fields to supermarkets.

One game-changing innovation that has emerged in the industry is the 40 x 48 x 43 Stackable Foldable IBCs. These versatile containers offer a wide range of benefits that revolutionize the way goods are transported, stored, and handled. This article delves into the features and advantages of 40 x 48 x 43 Stackable Foldable IBCs, emphasizing their role in enhancing efficiency and promoting sustainability.