Aerospace Container

September 14, 2021

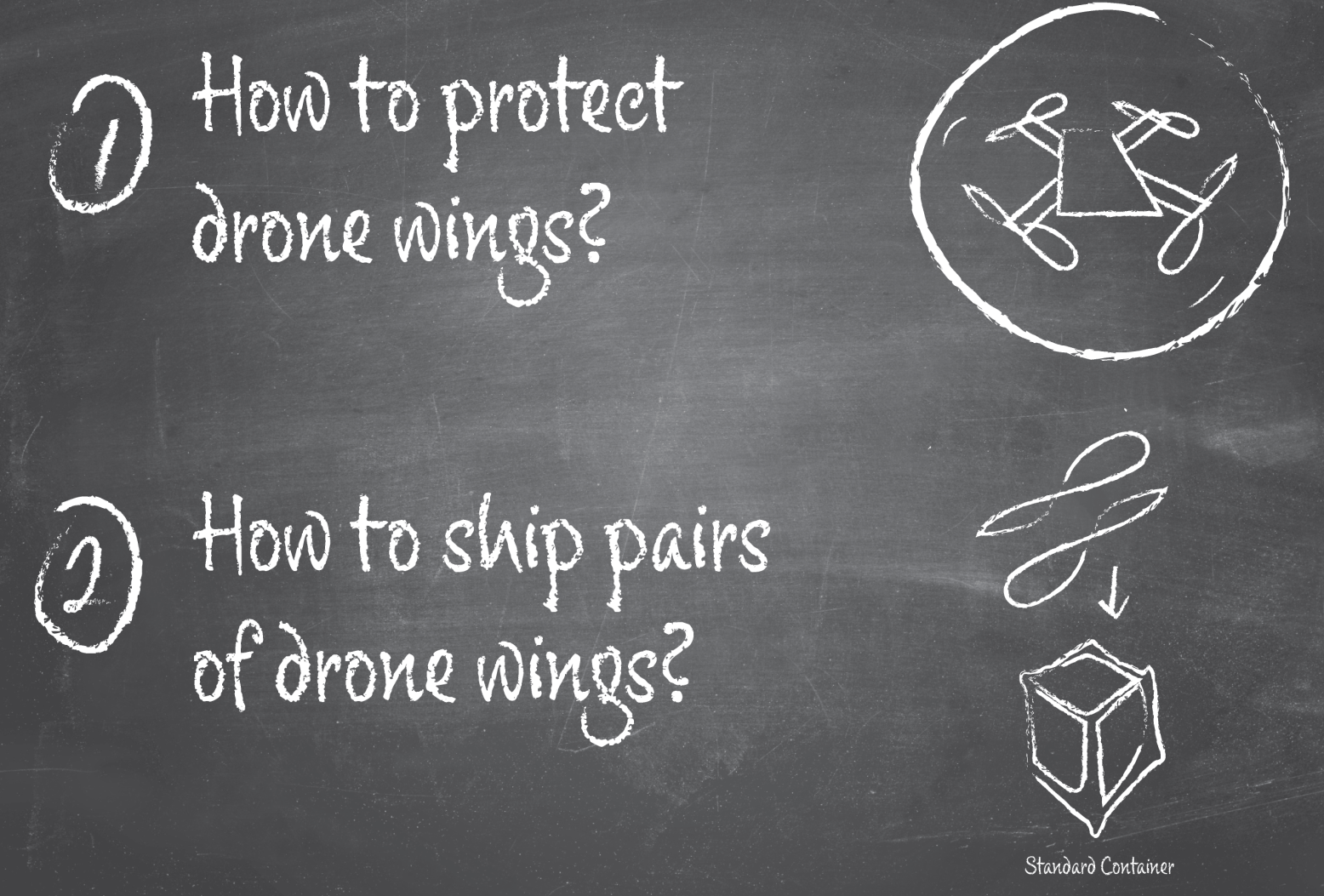

The Problem: How to protect and ship large pairs of valuable wings for drones?

We recently had a customer that needed a custom bin to ship extremely high-value wings for drones. No container existed with dimensions of a width roughly around 32" and a length around 90". The traditional larger bulk containers would not work because they are shipping the drone wings in sets and not large packages with large quantities of wings.

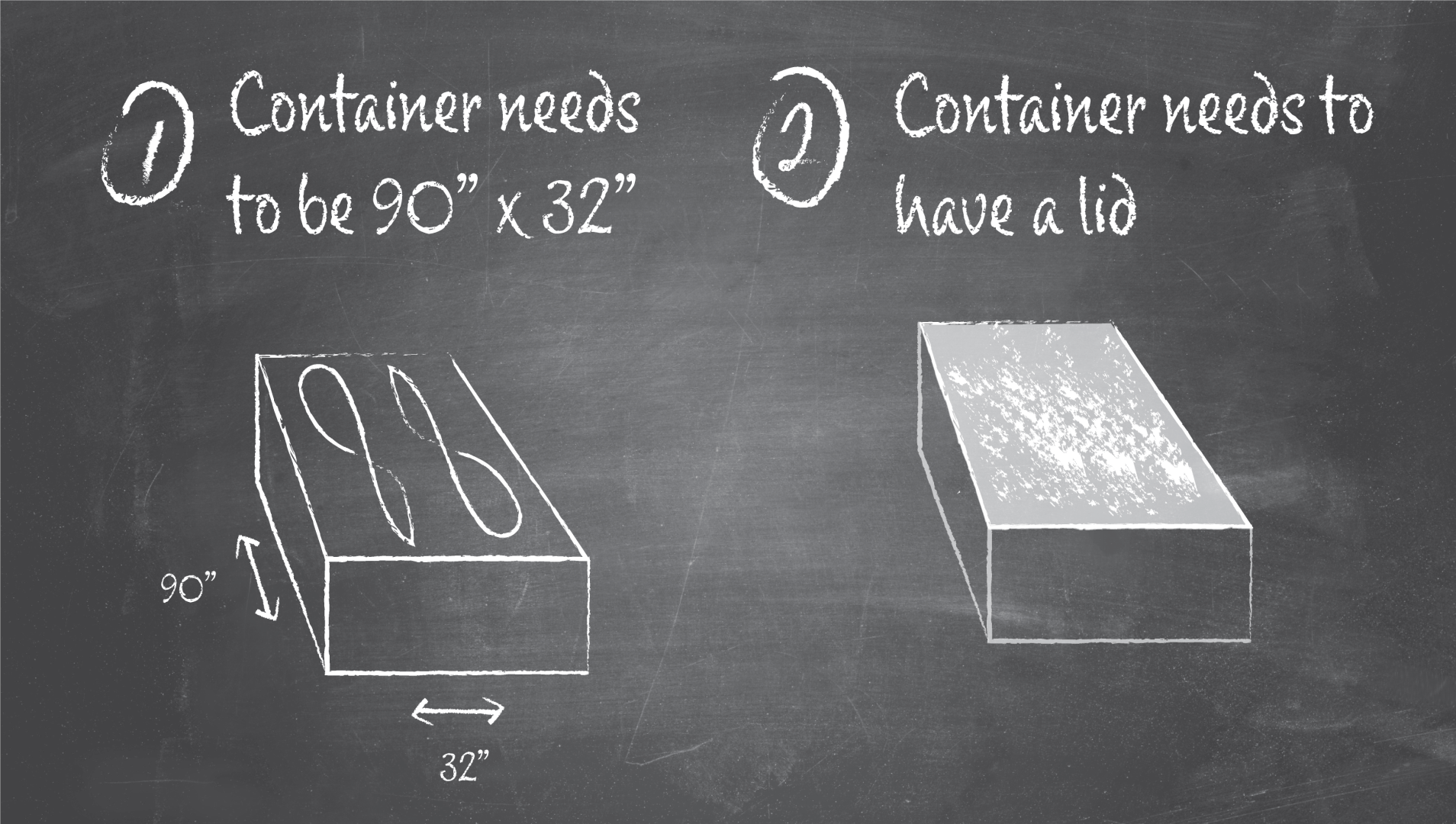

The Requirements:

The customer requested a strong, durable, and lightweight container with a lid. The container needed to have a 90" length and 32" width. The container needed to be lightweight but also strong and durable.

The Solution:

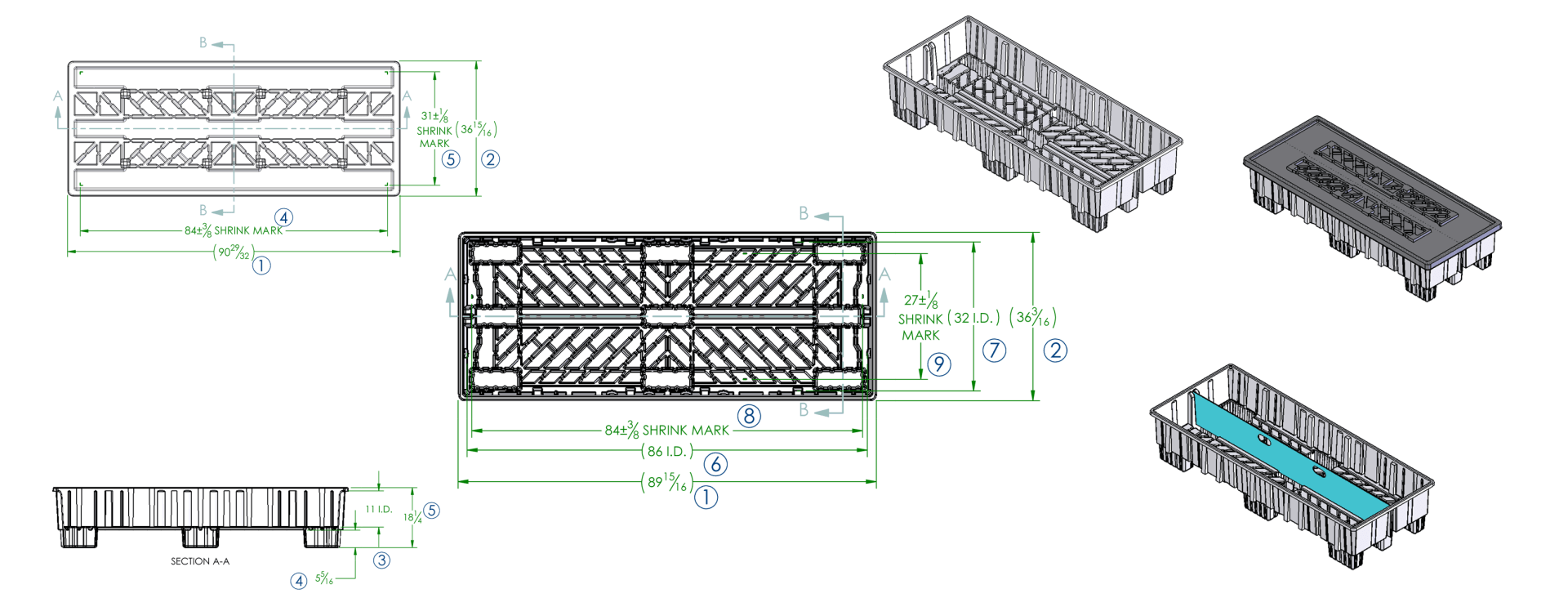

Our designers and engineers worked with a local thermoformer to create a completely custom mold for this project. Creating a thermoformed container would meet the requirements of the container being lightweight, and by creating a custom mold, we were able to get the exact dimensions that the customer needed.

Steel Reinforcements:

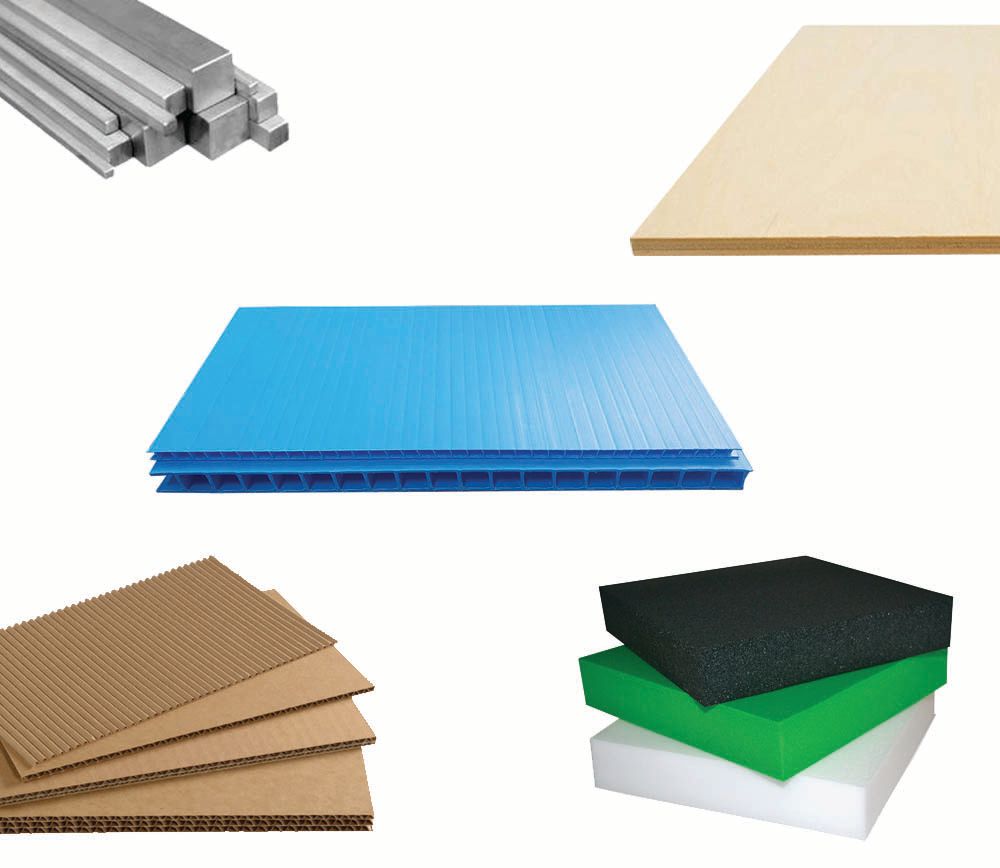

Next, we added steel reinforcements. Steel L-shaped bars were added to the top of the two long walls of the bin. Adding the steel bars to the top of the bin's walls increased the rigidity of the bin.

Plastic Divider:

A plastic divider was added to the center of the bin, running the length of the container. The divider's purpose is to keep the drone wings from shifting during shipment.

Metal Runners:

The last change we made was to increase the rigidity of the base of the bin by adding metal runners to the length and width of the base of the container. By adding the metal runners to the base, it will strengthen the base. The runners will also keep the container from flexing when a forklift is moving the bin. The metal runners also create fork straps for the container keeping it securely on the forks while being lifted and transported.

The Results:

By creating a custom-designed thermoformed bin and lid, we guarantee that the bin is exactly what the customer's applications need. Once the thermoformed bins and lids were created, our

CustomBulk®

technicians went to work adding L-shaped steel bars to the top of the bin's walls. Metal runners were also added to the base of each bin to give additional strength to the bins and creating fork straps. We were able to create a completely custom bin to meet the customer's very specific applications needs. The customer is now able to safely and securely ship and store their custom-length delicate drone wings.

Tyler Brady

|Sales Team Lead

Tyler is the Sales Team Lead, has been with RPP Containers for a decade, and has extensive knowledge and experience in the bulk container industry. Tyler works in tandem with our Custom Design Team to ensure all his customers find the optimum bulk container for their application.

When it comes to preserving the freshness and quality of your coffee beans, every detail matters—especially the storage containers you choose. In the world of coffee production, maintaining the integrity of the beans from roasting to final delivery is essential. That's where RPP Containers steps in with their reliable plastic hopper bottom containers, a game-changer for anyone involved in the coffee business, from roasters to retailers.

In the world of material handling and logistics, one size does not fit all. That's where RPP Containers steps in with its innovative CustomBulk solutions, designed to address the unique challenges businesses across various industries face. Whether you're dealing with oversized components or sensitive materials or need something beyond the standard container offerings, CustomBulk by RPP Containers is your go-to for tailored, practical solutions.

In the ever-evolving world of industrial storage, reliable, efficient, customizable bulk containers are paramount. Companies across various sectors—from manufacturing to logistics—require storage solutions that meet their unique specifications and enhance operational efficiency. This is where RPP Containers steps in with its innovative custom bulk containers designed to address these precise needs.

In the world of industrial storage and transportation, efficiency and durability are paramount. As businesses strive to optimize their operations, the demand for innovative storage solutions has never been higher. One such innovation that has gained significant traction is custom plastic bulk containers with ramp walls. These containers are revolutionizing the way industries handle bulk materials, offering many benefits catering to various needs. In this blog post, we will explore the advantages of these containers, their applications, and why they are becoming the go-to choice for many businesses.

Bulk containers are an essential part of many industrial and commercial operations, providing a convenient and scalable solution for transporting and storing a wide variety of goods. However, as businesses evolve and adapt to changing needs, there often arises a necessity to modify the walls of these bulk containers to better suit their specific requirements. Whether it’s reinforcing the structure, adding access points, or enhancing insulation, wall modifications can significantly enhance the efficiency and functionality of bulk containers.

When shipping and storing goods in bulk containers, ensuring the safety and integrity of the products is of the utmost importance. This is where bulk container dunnage comes into play. Dunnage refers to materials used to support and secure cargo during transportation, and when it comes to bulk containers, the use of dunnage becomes even more crucial.

Returnable bulk containers, a sustainable choice, are extensively used in the automotive supply chain to transport and store various components and materials required in manufacturing. Their durable and reusable design makes them an economical option and a significant step towards reducing single-use packaging and promoting environmental responsibility.

Agriculture, particularly fruit and vegetable growing and processing, is a very demanding business. It requires highly efficient, strong packaging and is resistant to harsh environments. RPP Containers has been at the forefront of meeting these needs. Our DuraGreen vented harvest bins and solid wall bulk bins protect produce, ensure quality, and preserve freshness from fields to supermarkets.

One game-changing innovation that has emerged in the industry is the 40 x 48 x 43 Stackable Foldable IBCs. These versatile containers offer a wide range of benefits that revolutionize the way goods are transported, stored, and handled. This article delves into the features and advantages of 40 x 48 x 43 Stackable Foldable IBCs, emphasizing their role in enhancing efficiency and promoting sustainability.