Step-By-Step - CenterFlow Seed Boxes Nesting and Assembly

Did you know that the CenterFlow Seed Box collapses?

The CenterFlow Hopper Bottom container is a staple of the seed industry. Its smooth, funnel-shaped interior is ideal for seed and grain and pellets, resins, and powders. Constructed of high-density polyethylene plastic means that it will not rust, peel, or splinter while handling thousands of pounds per load. The 35-degree angle of the chute ensures a steady flow of product, and an adjustable slide allows the container to be emptied in as little as 30 seconds. What many people don’t know, though, is that they can also be collapsed.

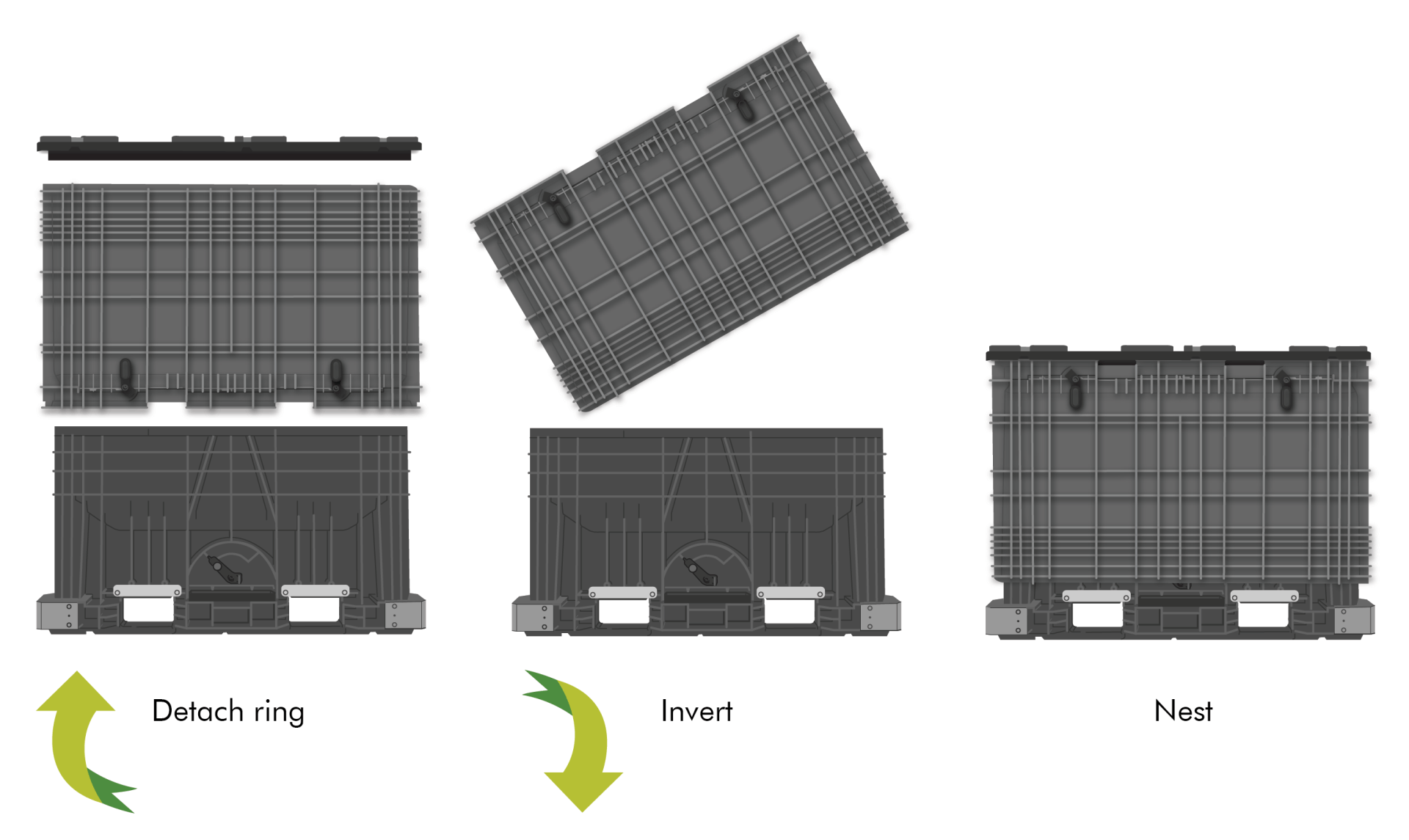

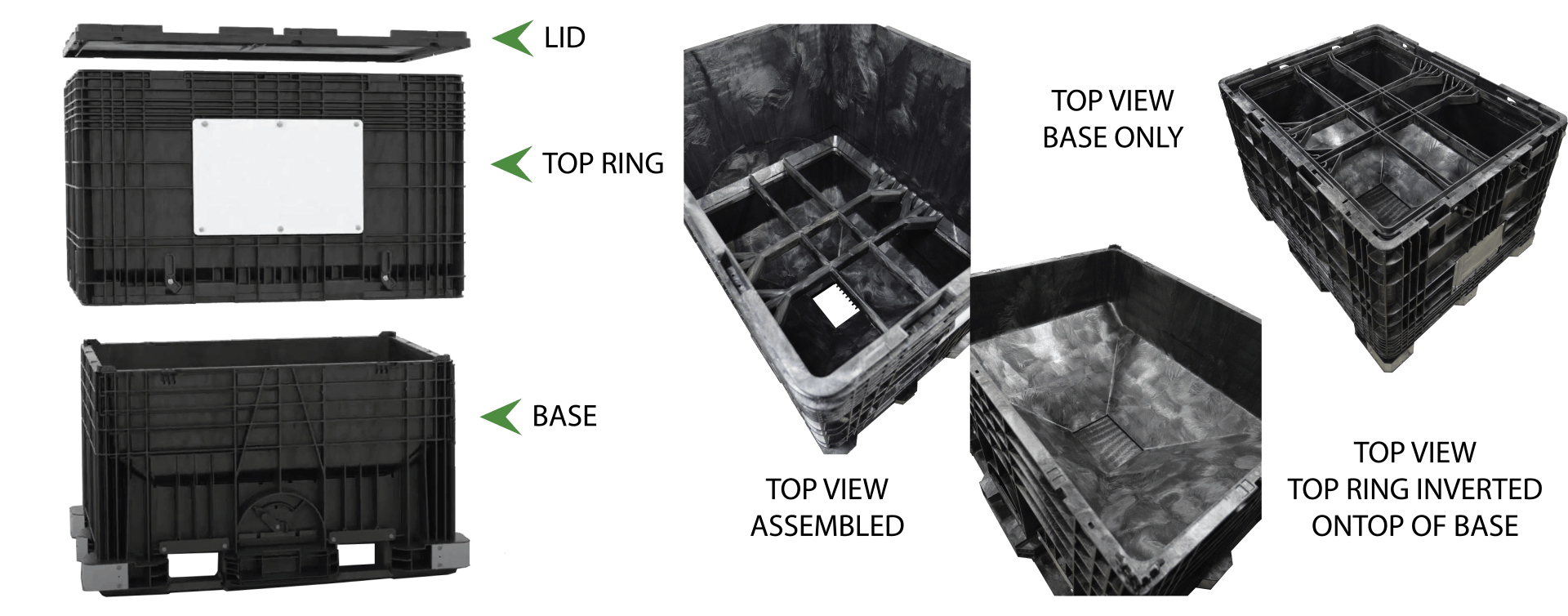

For the purposes of shipping or storage during the off-season, the CenterFlow Hopper Bottom can reduce its height to save up to 40% space. This helps to reduce the cost for them to arrive to you and increases the return ratio if you ship them in a closed-loop system. It accomplishes this feat in a way very different from standard collapsible bulk containers. The top half of the container is pulled away from the bottom, flipped upside down, and reattached over the bottom section, reducing the overall height while still allowing it to be moved with a forklift.

The last thing to do is lock the eight latches, which will secure the top to the base. The lid can be placed back on top if needed. It is now operational and ready to be loaded. This same technique will work for the 65” and 74 ” versions.