1-800-945-8304 | contact@rppcontainers.com | Live Chat

Shock-Absorbent Containers

April 28, 2021

The Problem: How to protect and ship a highly calibrated machine without causing misalignment?

We recently had a customer that needed to ship delicate items overseas. The product was a highly calibrated machine, but the roughness of the road and jostling on the ocean was causing the calibration to become off. This was an expensive product, and it was suffering misalignment during transportation before even reaching the customer. It needed to be protected from not only sliding but also the vibration of transportation. We were able to come up with a solution to secure the machine tightly to the base of the container and made the base itself able to absorb the shock of the road.

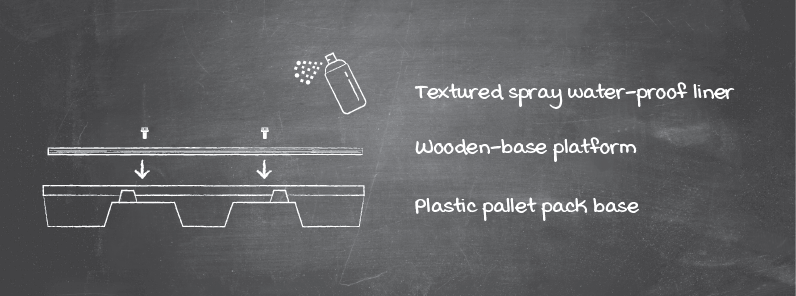

Step One:

We started with a wood-based platform that would be mounted to the pallet pack base. This provided decent strength at a lower cost to the customer. To protect the wood from rot, we added a water-proof liner to the boards. The liner also added texture to help add some grip to prevent the merchandise from sliding. With a base to start with, we could move on to securing the customer’s product.

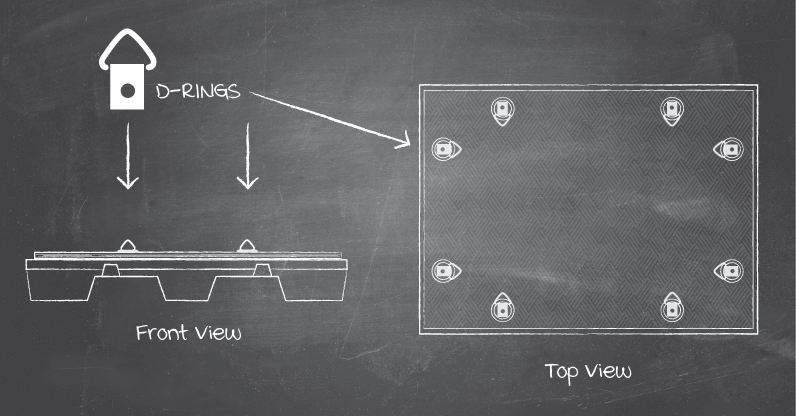

Step Two:

Next, we needed to take care of securing the machine to the wooden platform on the container. If the product was left loose, it wouldn’t matter how good a shock absorber the floor was. A big enough bump in the road could still send the merchandise bouncing or sliding, undoing the calibration. To prevent this, we installed multiple D-Rings along the floor in specific locations so the customer could tightly secure the machine in place.

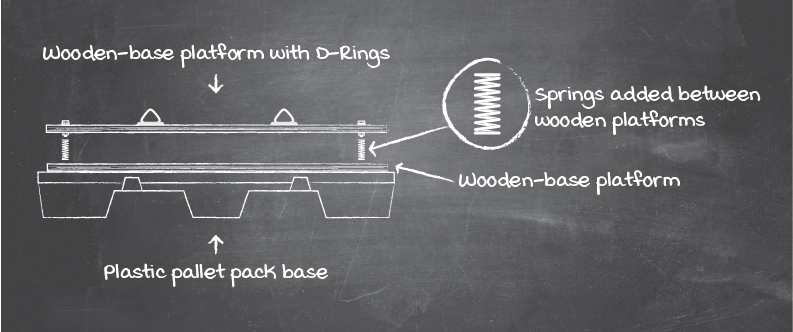

Step Three:

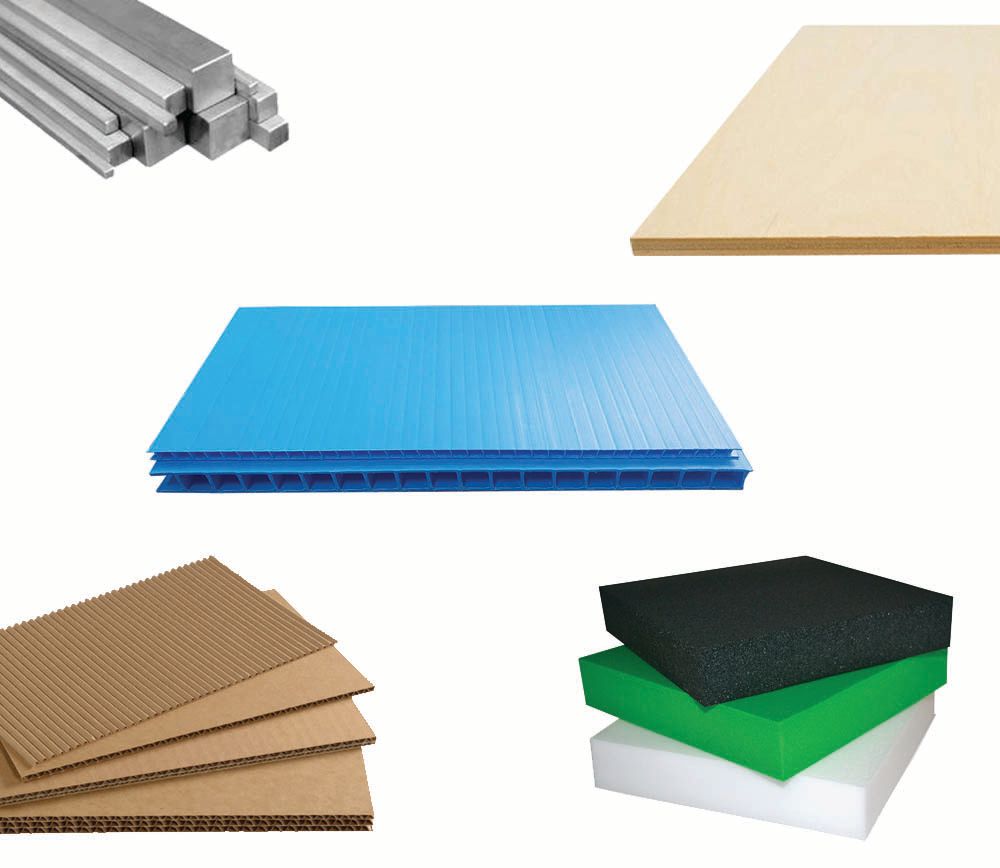

The last change we made to increase protection was to make the base itself a shock-absorbent platform. This would help cut out all the vibrations from the drive to the product’s final destination, saving the company from product damage during transportation. By taking another board to the platform and installing strong springs in the corners, we could assure a strong base with a good amount of absorption. The springs were designed to be adjustable to handle the weight of the customer’s product while handling vibrations from shipping. For added protection, we sandwiched a layer of permeable foam between the panels.

With these modifications, the customer could be sure that their merchandise was safe, secure and would maintain the calibration along its route. The D-rings and textured liner allowed them to tightly secure their machine to the base of the container to prevent any sliding. The springs and foam helped to protect against the shock that was ruining the alignment of the merchandise.

Taylor Turner

|Account Manager

Taylor has been with RPP Containers for eight years as an account manager and has extensive knowledge and experience in the bulk container industry. Taylor works closely with all his customers to find the optimum bulk container for the customer's application.

By Emily Wilhelmus

•

February 19, 2025

In the world of material handling and logistics, one size does not fit all. That's where RPP Containers steps in with its innovative CustomBulk solutions, designed to address the unique challenges businesses across various industries face. Whether you're dealing with oversized components or sensitive materials or need something beyond the standard container offerings, CustomBulk by RPP Containers is your go-to for tailored, practical solutions.

By Emily Wilhelmus

•

November 13, 2024

In the ever-evolving world of industrial storage, reliable, efficient, customizable bulk containers are paramount. Companies across various sectors—from manufacturing to logistics—require storage solutions that meet their unique specifications and enhance operational efficiency. This is where RPP Containers steps in with its innovative custom bulk containers designed to address these precise needs.

By Emily Wilhelmus

•

October 21, 2024

In the world of industrial storage and transportation, efficiency and durability are paramount. As businesses strive to optimize their operations, the demand for innovative storage solutions has never been higher. One such innovation that has gained significant traction is custom plastic bulk containers with ramp walls. These containers are revolutionizing the way industries handle bulk materials, offering many benefits catering to various needs. In this blog post, we will explore the advantages of these containers, their applications, and why they are becoming the go-to choice for many businesses.

By Emily Wilhelmus

•

September 30, 2024

Bulk containers are an essential part of many industrial and commercial operations, providing a convenient and scalable solution for transporting and storing a wide variety of goods. However, as businesses evolve and adapt to changing needs, there often arises a necessity to modify the walls of these bulk containers to better suit their specific requirements. Whether it’s reinforcing the structure, adding access points, or enhancing insulation, wall modifications can significantly enhance the efficiency and functionality of bulk containers.

By Emily Wilhelmus

•

September 18, 2024

When shipping and storing goods in bulk containers, ensuring the safety and integrity of the products is of the utmost importance. This is where bulk container dunnage comes into play. Dunnage refers to materials used to support and secure cargo during transportation, and when it comes to bulk containers, the use of dunnage becomes even more crucial.

By Emily Wilhelmus

•

August 20, 2024

Returnable bulk containers, a sustainable choice, are extensively used in the automotive supply chain to transport and store various components and materials required in manufacturing. Their durable and reusable design makes them an economical option and a significant step towards reducing single-use packaging and promoting environmental responsibility.

By Emily Wilhelmus

•

July 25, 2024

Agriculture, particularly fruit and vegetable growing and processing, is a very demanding business. It requires highly efficient, strong packaging and is resistant to harsh environments. RPP Containers has been at the forefront of meeting these needs. Our DuraGreen vented harvest bins and solid wall bulk bins protect produce, ensure quality, and preserve freshness from fields to supermarkets.

By Emily Wilhelmus

•

April 24, 2024

RPP Containers®, a leading manufacturer and stocking distributor of reusable bulk containers, has developed the next generation of 45" x 48" x 50" Collapsible Hopper Bottom Containers for the DuraGreen® line of premium products that promote environmental sustainability™.

By Emily Wilhelmus

•

February 5, 2024

One game-changing innovation that has emerged in the industry is the 40 x 48 x 43 Stackable Foldable IBCs. These versatile containers offer a wide range of benefits that revolutionize the way goods are transported, stored, and handled. This article delves into the features and advantages of 40 x 48 x 43 Stackable Foldable IBCs, emphasizing their role in enhancing efficiency and promoting sustainability.

By Emily Wilhelmus

•

October 23, 2023

Fixed wall bulk containers have become indispensable in various industries thanks to their durability, versatility, and efficiency. This blog post will explore how these containers are used and how they have revolutionized storage and transportation processes across different sectors.