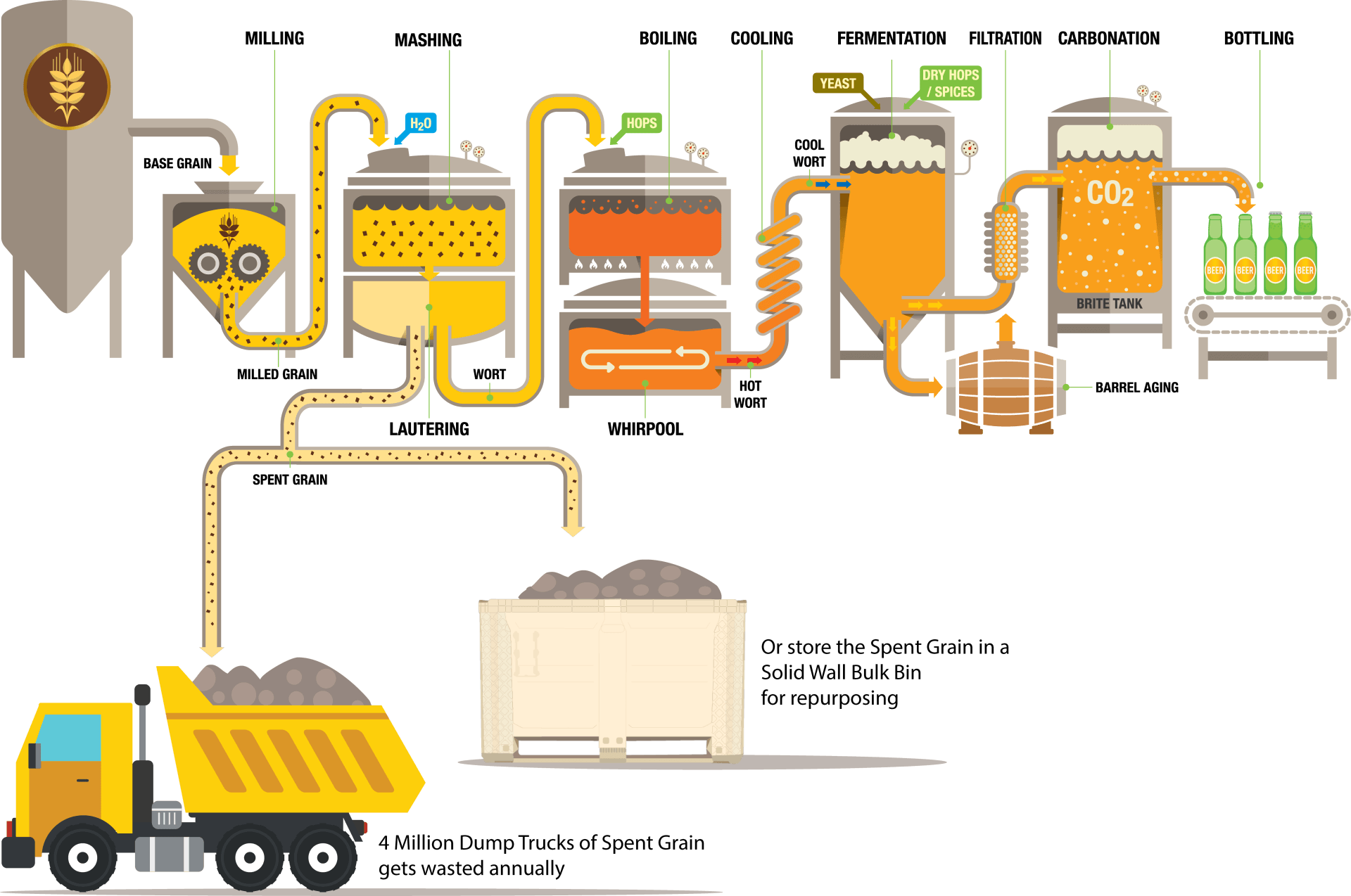

What are spent grains? Spent grain is a term used in the brewing industry that describes the malted barley and other grains after a brewery has already used it to make beer. Malt is generally made from soaked, sprouted, and dried barley. Once the grain is deemed "spent," it means it can no longer be used to produce more beer.

Where do spent grains come from?

Spent grain is what is leftover after breweries have made beer. Did you know that every six-pack of beer uses approximately one pound of malted barley and other grains? From that one pound of dry malted barley and grain, it produces 1 1/4 pounds of wet spent grains. Every year in the US alone, 20 Billion pounds of brewers' spent grain is created.

Unfortunately, breweries discard most of the spent grain because they have no way to store or efficiently transport it. It is estimated that four million dump trucks of spent grain get wasted by breweries in the US annually.

How to transport and store spent grain?

Once the grain is spent, it can be stored in a DuraGreen FDA-approved bulk bin instead of being discarded. Spent grains contain a large number of proteins, sugars, and minerals that can cause microbial growth if the gain is not refrigerated, frozen, or quickly dried. If the spent grain stays at room temperature too long, it can turn sour. DuraGreen FDA-approved bulk bins can be taken straight into large refrigerated storing areas.

We offer several sizes of

solid wall bulk bins that are ideal for storing and transporting spent grains. These solid wall bulk bins are FDA Approved and made from a non-porous material that is easy to clean and won’t breed bacteria.

Four ways to reuse spent grains

Repurposing spent grains has started picking up in popularity in recent years, and below is a list of the most popular uses for spent grains.

The easiest way to reuse spent grain is to work it into your composting. Spent brewery grain is classified as nitrogenous waste, meaning it is high in green matter such as grass clippings and leaf matter or straw. Remember to use a 2:1 ratio of green matter to brown matter.

A simple way to use spent grains as compost is to put them directly in the ground. Mix the spent grains into the soil of your vegetable gardens and flower beds.

Spent grains can be used as filler for homemade dog treats.

HOPS ARE TOXIC TO DOGS, do not use spent grains that have come into contact with hops. Do not make treats from spent grains that were used to make

wheat ale. Barley and oats are popular treats for dogs.

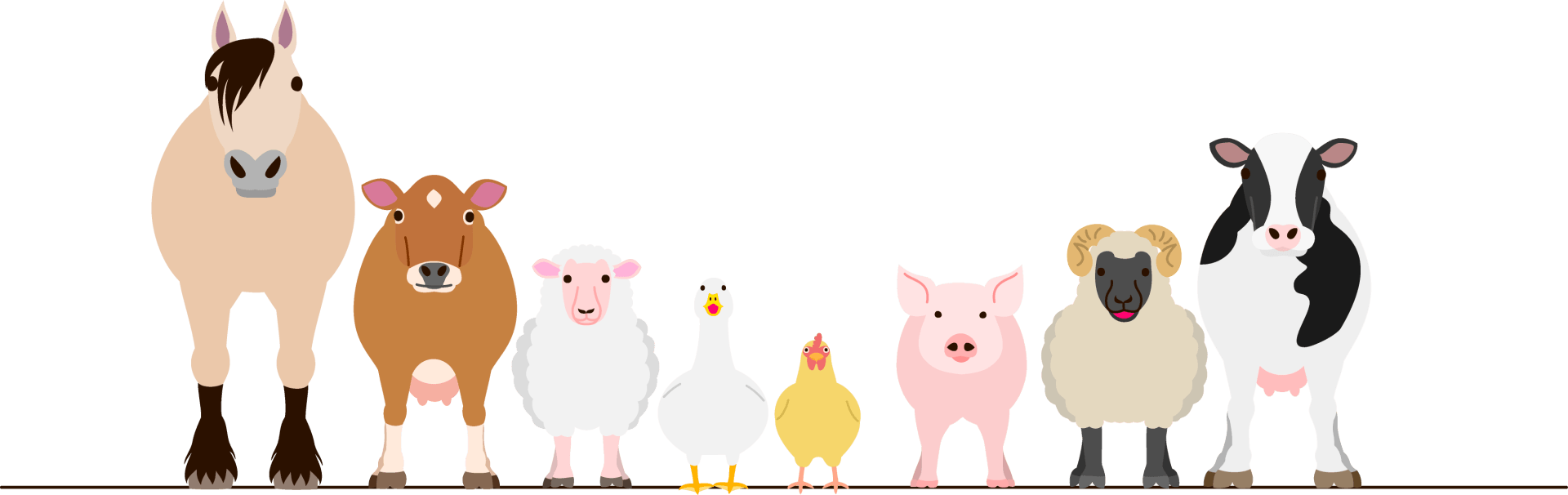

Spent grains are a good source of supplemental feed for animals such as horses, pigs, sheep, cows, and chickens. If the spent grain is wet, it must be used quickly because it will spoil quickly. If the grain is moldy or appears to have turned, do not feed it to your livestock. Put it into compost. Spent grains are not a replacement for traditional feed and should not be the bulk of the animal's feed.

Did you know that you can use recently spent grains in cooking and baking? The grain can be used wet after most of the liquid has been pressed out of the grain. Wet spent grain can be used in small amounts to add texture and flavor to bread and various baked goods.

Dried spent grains can be dried and ground into flour. Drying spent grain can be done over the course of several hours by using a conventional oven. Spread the spent grain on a cookie sheet with a half-inch thickness. Set your oven's temperature to its lowest setting, around 170°F, and place the cookie sheet of spent grain in the oven. Keep the oven door cracked so that the moisture of the spent grain can escape. Check the progress of the grain every so often to stir the spent grain to check the moisture content and ensure that you are not burning the grain. The objective is to dry out the spent grain without actually cooking it or burning it.

Once the spent grain is dried, it can be milled into flour. This can be done in a grain mill, a standard food processor, or even a coffee grinder. The setting of your machine and duration depend on how fine you want your flour to be. Once you are happy with the consistency of the flour, you are ready to bake.

Do you have questions about solid wall bulk bins?

Solid wall bulk bins are the ideal solution for all spent grain storage and transporting needs.

DuraGreen solid wall bulk bins are durable and long-lasting for repeated usage year after year, and they are also

recyclable. If you don't see a bulk bin that will fit your specific application, we offer

custom solutions. Do you have questions? Call 513-489-2244 to speak to one of our knowledgeable account managers.