JIT Manufacturing

March 31, 2021

What is JIT Manufacturing?

JIT Manufacturing, also known as Just-In-Time Manufacturing, is a methodology for reducing cost and increasing production speed, as well as flow from vendors. The time it takes to get your product to market and the cost associated with manufacturing can make or break a company. JIT aims to simplify processes, allowing for increased productivity and lowered costs.

Developed in post-World War II Japan, this type of lean manufacturing was the response to Japan’s economic climate. The large inventory production methods used in other countries were too expensive for them to finance. In response, they focused on smaller factories and smaller batches of products. This lowered financial risk, while maintaining sustainable levels of capital.

There are a few keys to JIT Manufacturing: organization; elimination of defects; small batch sizes; managing flow; streamlining product movement; and kanban. If done properly, you can see a radical change in productivity, risk, and operation costs.

RPP Containers

can help with a few of these tasks.

By having uniform containers for storage, you increase the ease of organization.

Collapsible bulk containers

stack efficiently and safely. When it comes time to retrieve your materials, there isn’t lost time trying to dig them out or keep a stack balanced. A forklift driver can pull up, select the containers, and get the product where it needs to be. This helps ensure a steady workflow.

RPPs' bulk bins'

have a high weight capacity and durability means you can accomplish what your competitors can with much less space. This means you have more area for your processes. Space is money. Not just when building, but also in maintaining. Reducing your operation's overall size is a major cost savings that will greatly benefit your company for years to come.

By establishing a closed-loop system with your vendors, you can greatly increase organization. Having uniform packaging makes organizing easy. This means that having your needed supplies arriving in

containers

that are compatible to your in-house packaging can be a huge benefit.

Reusable collapsible totes

are the perfect option for this kind of closed loop system. Their high nesting ratio means you are able to select the storage your supplies arrive in and can get that same packaging back to your suppliers for reduced cost.

Easy to understand labeling can also reduce time for accessing stored products or WIP.

RPP Containers

offers a variety of ID Tags and easy-release placards to help identify what each container holds. This will help to maintain your workflow and organize your plant in an efficient way.

RPP Containers makes implementing JIT practices easy, allowing you to focus your attention on other things, like growing your business.

Taylor Turner

|Account Manager

Taylor has been with RPP Containers for eight years as an account manager and has extensive knowledge and experience in the bulk container industry. Taylor works closely with all his customers to find the optimum bulk container for the customer's application.

When it comes to preserving the freshness and quality of your coffee beans, every detail matters—especially the storage containers you choose. In the world of coffee production, maintaining the integrity of the beans from roasting to final delivery is essential. That's where RPP Containers steps in with their reliable plastic hopper bottom containers, a game-changer for anyone involved in the coffee business, from roasters to retailers.

In the world of material handling and logistics, one size does not fit all. That's where RPP Containers steps in with its innovative CustomBulk solutions, designed to address the unique challenges businesses across various industries face. Whether you're dealing with oversized components or sensitive materials or need something beyond the standard container offerings, CustomBulk by RPP Containers is your go-to for tailored, practical solutions.

In the ever-evolving world of industrial storage, reliable, efficient, customizable bulk containers are paramount. Companies across various sectors—from manufacturing to logistics—require storage solutions that meet their unique specifications and enhance operational efficiency. This is where RPP Containers steps in with its innovative custom bulk containers designed to address these precise needs.

In the world of industrial storage and transportation, efficiency and durability are paramount. As businesses strive to optimize their operations, the demand for innovative storage solutions has never been higher. One such innovation that has gained significant traction is custom plastic bulk containers with ramp walls. These containers are revolutionizing the way industries handle bulk materials, offering many benefits catering to various needs. In this blog post, we will explore the advantages of these containers, their applications, and why they are becoming the go-to choice for many businesses.

Bulk containers are an essential part of many industrial and commercial operations, providing a convenient and scalable solution for transporting and storing a wide variety of goods. However, as businesses evolve and adapt to changing needs, there often arises a necessity to modify the walls of these bulk containers to better suit their specific requirements. Whether it’s reinforcing the structure, adding access points, or enhancing insulation, wall modifications can significantly enhance the efficiency and functionality of bulk containers.

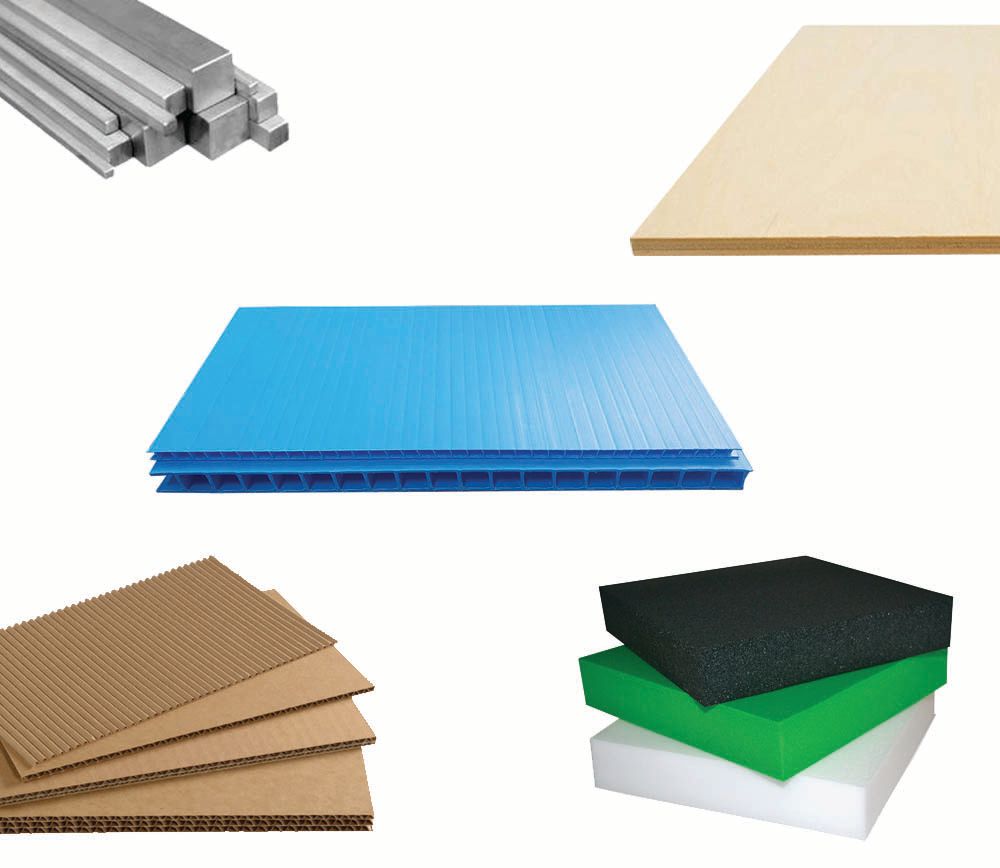

When shipping and storing goods in bulk containers, ensuring the safety and integrity of the products is of the utmost importance. This is where bulk container dunnage comes into play. Dunnage refers to materials used to support and secure cargo during transportation, and when it comes to bulk containers, the use of dunnage becomes even more crucial.

Returnable bulk containers, a sustainable choice, are extensively used in the automotive supply chain to transport and store various components and materials required in manufacturing. Their durable and reusable design makes them an economical option and a significant step towards reducing single-use packaging and promoting environmental responsibility.

Agriculture, particularly fruit and vegetable growing and processing, is a very demanding business. It requires highly efficient, strong packaging and is resistant to harsh environments. RPP Containers has been at the forefront of meeting these needs. Our DuraGreen vented harvest bins and solid wall bulk bins protect produce, ensure quality, and preserve freshness from fields to supermarkets.

One game-changing innovation that has emerged in the industry is the 40 x 48 x 43 Stackable Foldable IBCs. These versatile containers offer a wide range of benefits that revolutionize the way goods are transported, stored, and handled. This article delves into the features and advantages of 40 x 48 x 43 Stackable Foldable IBCs, emphasizing their role in enhancing efficiency and promoting sustainability.